MCM-100: Monitoring system helps to save servicing costs for machines

Servicing and maintenance costs for machines can be reduced considerably if continuous vibration monitoring warns against abnormalities early enough. In this case, on the one hand the time for servicing can be self-determined for maintenance in order to avoid production interruptions and on the other hand early intervention enables the hindrance of larger-scale damages. A compact and cost-efficient system for high-speed oscillation data analysis is now available from Acceed. It consists of a compact industrial Box PC as well as optional sensors, software and radio modules (WLAN, 4G).

Rotating elements in machines normally generate even oscillations. Cracks and breaks arise as a result of changed oscillation frequencies, in particular on shafts and bearings. You simply need to recognise them early in order to anticipate sudden failure and standstills. Sound emission testing based on high-speed data recording serves to recognise damages to roller bearings early and a compact industrial system is available for this purpose from Acceed.

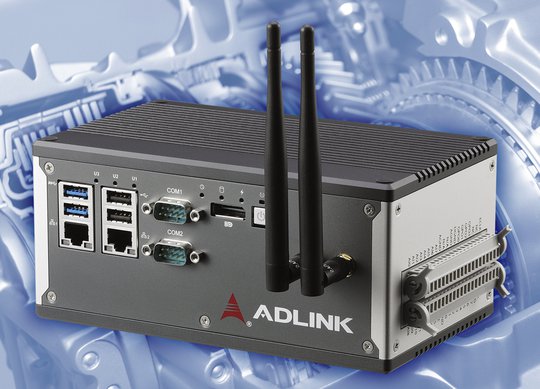

The condition monitoring platform MCM-100 in a full-aluminium casing from the manufacturer Adlink enables 24/7 monitoring of oscillating components with a high degree of precision and scanning rate. The fanless all-in-one computer is already equipped with the specific measurement technology and offers data recording, calculation and analysis as a compact package with stable and secure network connection. The automatic recording of machine information for long-term analysis and the recognition of trends is an additional advantage.

The embedded PC is driven by the Atom processor x7-E3950 from Intel. Up to four 24-bit channels, each with 128 kS/s, are available for simultaneous measurement value recording. The optional acceleration sensor can be attached using a magnet, making attachment easy at any desired measurement location and avoiding costs and work as incurred with fixed, screwed measuring sensors. Data communication takes place via two GbE interfaces or an optional radio module (WLAN or G4). An mSATA-SSD with 128 GB capacity is already integrated for local storage. Serial interfaces, four USB ports, two mini PCIe slots and the high resolution display port round-off the equipment. Windows 10 IoT Enterprise and Core as well as Ubuntu Linux are supported as operating systems. Therefore, the MCM-100 is immediately ready for use.

With its really compact dimensions of 183 x 110 x 84 mm, the aluminium casing is also suitable for top-hat rail assembly. The admissible ambient temperature for operation is defined with 0 to 55 °C. Further technical details and information regarding application options are available directly from Acceed.

Conclusion: due to simple software handling for the analysis of acoustic emissions, the system which is based on the MCM-100 can be used immediately and mobile can, for example, help to identify the formation of cracks as a result of material fatigue, overloading or servicing deficiencies and therefore also enable early predictions of roller bearing damages.