POC-200: Unleashed IIoT by example of water quality

The method of unleashed flashes is familiar in photography. The simple idea of “freeing” the two interlinked system components camera and flash and the creation of more leeway for creativity and application options via disengagement is concealed behind this somewhat sensational term. This simple, but highly efficient method can also be applied to the Industrial Internet of Things (IIoT). Instead of restricting oneself to a package of interlinked system components from a single manufacturer, system architecture with project-specific tailored selection of components from various manufacturers offers optimum performance and that often at more favourable terms. Here, both data communication and hardware interaction are secured with tailored software.

If we have to do with tailored software, the issue is often the nightmare of the exorbitantly expensive individual solution. The worry: one single project must bear all the costs of software development. Within the scope of the IIoT, the situation is actually rather different. The basic software can often be acquired at very reasonable prices or is even provided free of charge alongside the hardware. Normally, the interfaces are open. So, related to the project it is “only still” a question of defining the ideal communication routes and of optimally implementing interplay programmatically. The company Acceed, to-date primarily renowned as a distributor, specialises in precisely this process. Acceed has long since recognised that the best solution does not consist in banking on a single brand or only one manufacturer. In particular, the highly motivated and innovative developers from Asia normally concentrate on one technical and thematic focal point, where they bundle all their strengths. The times of the vendor’s tray, who offers something for everyone, but unfortunately no top performance, are times of the past. The knowledge of specialised developers’ top technology enables Acceed to think and plan out of the box - manufacturer-independently. With own software development attuned to the respective customer project, Acceed then brings intrinsic intelligence into the system.

A simple example illustrates the interaction of hardware selection and software development. When bottles are cleaned at bottling plants, NaOH (sodium hydroxide) is also used. The use of the alkaline solution increases the pH value in waste water. As a result, the microorganisms from the biological treatment stages can no longer reduce the nitrogen compounds efficiently. In order to prevent damages to these microorganisms and additionally to water flora and fauna in general, it is necessary to constantly measure the pH value locally at different locations. To-date, these measurements are carried out manually by sewage specialists from treatment plants or external laboratories, meaning high staff, material, work and travel costs. Moreover, the actual number of measurements is restricted due to the staff resources available.

In collaboration with a measurement and control technology supplier, Acceed developed a system for the automated recording and central evaluation of measurement data for the allocated measurement locations. In addition to the pH probes, the hardware used consists of a gateway, an industrial POC-210 series box computer, a microcontroller programmed by Acceed and software developed by Acceed to evaluate and visualise the measurement data.

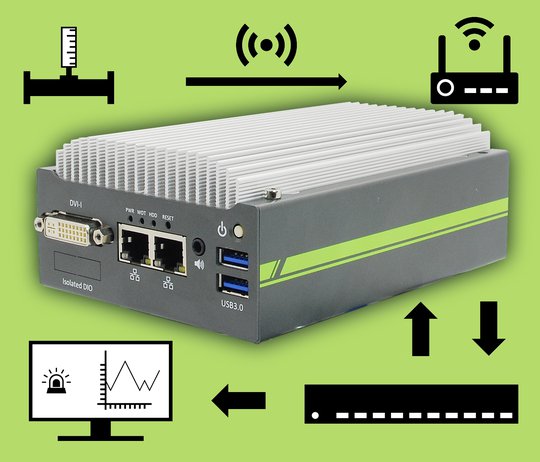

The microcontroller programmed by Acceed reads the pH probe measurement values via the modbus RTU protocol. They are then transmitted to a gateway via a LoRaWAN transmission path. Thus, the data from measurement locations which are difficult to access in the sewage channel is also transmitted as energy efficiently as possible, also over long distances, at regular intervals. Depending on the sensors used, the LoRaWAN technology is also appropriated for use in ATEX environments which are subject to the restrictions of Zone 1, gas zone IIb. The data is transferred via the Ethernet from the gateway to the central series POC-210 box computer. Storage (MySQL), evaluation and visualisation (NodeRed) take place there. In addition to documentation and visualisation, it is also possible to output alarms if limit values are exceeded. Thus, the necessary sewage controls can be implemented more efficiently, audit-proof and more cheaply. Problematic pH measurement values are recognised without time delays, enabling timely and effective intervention before more serious impairment is incurred.

The POC-210 is an industrial, fanless box computer and is equipped specifically for projects and configured as a Linux server by Acceed. Alternatively, also the installation of a LoRaWAN card in the mPCIe slot would be possible if there is no space available for a separate gateway. Thanks to the universal box computer, the system can always be extended by integrating additional components as required.

As a distributor with several years’ experience, Acceed is able to pay attention to the best possible mutual benefits and optimum interplay with regard to the expected functions when selecting the hardware it offers and configure it specifically for the respective project. In addition to programming its use, device-specific snippets can also be provided for integration in the customer’s existing communication structures.